The Ultimate Guide to Choosing the Right Injection Mold Supplier

When it comes to the manufacturing industry, the choice of a reliable injection mold supplier is critical for the success of your business. Whether you are producing components for the automotive industry, electronics, or consumer goods, the quality of the molds used in the injection process can significantly affect the final product. This article will guide you through the essentials of selecting the right supplier and the myriad benefits they can provide.

Understanding Injection Molding and Its Importance

Injection molding is a manufacturing process used for producing parts by injecting material into a mold. This technique is favored for its efficiency and ability to create complex geometries. High-quality molds lead to quality products, making the choice of an injection mold supplier paramount.

Benefits of Injection Molding

- High Efficiency: Once a mold is designed and built, it can produce thousands of parts quickly.

- Cost-effective for High Volume: After the initial investment, the cost per unit decreases with volume.

- Precision and Repeatability: Injection molded products are consistent in size and quality.

- Diverse Materials: An array of plastics and other materials can be injected for different applications.

Qualities to Look for in an Injection Mold Supplier

Choosing an injection mold supplier is not a decision to take lightly. Here are some essential qualities and considerations to ensure you find the best fit for your business needs:

1. Experience and Expertise

Experience in the industry often correlates with a supplier’s ability to deliver high-quality products. An experienced injection mold supplier will be familiar with common pitfalls and advanced techniques in mold design and manufacturing. Look for suppliers who have a proven track record and a portfolio showcasing their previous work.

2. Advanced Technology and Machinery

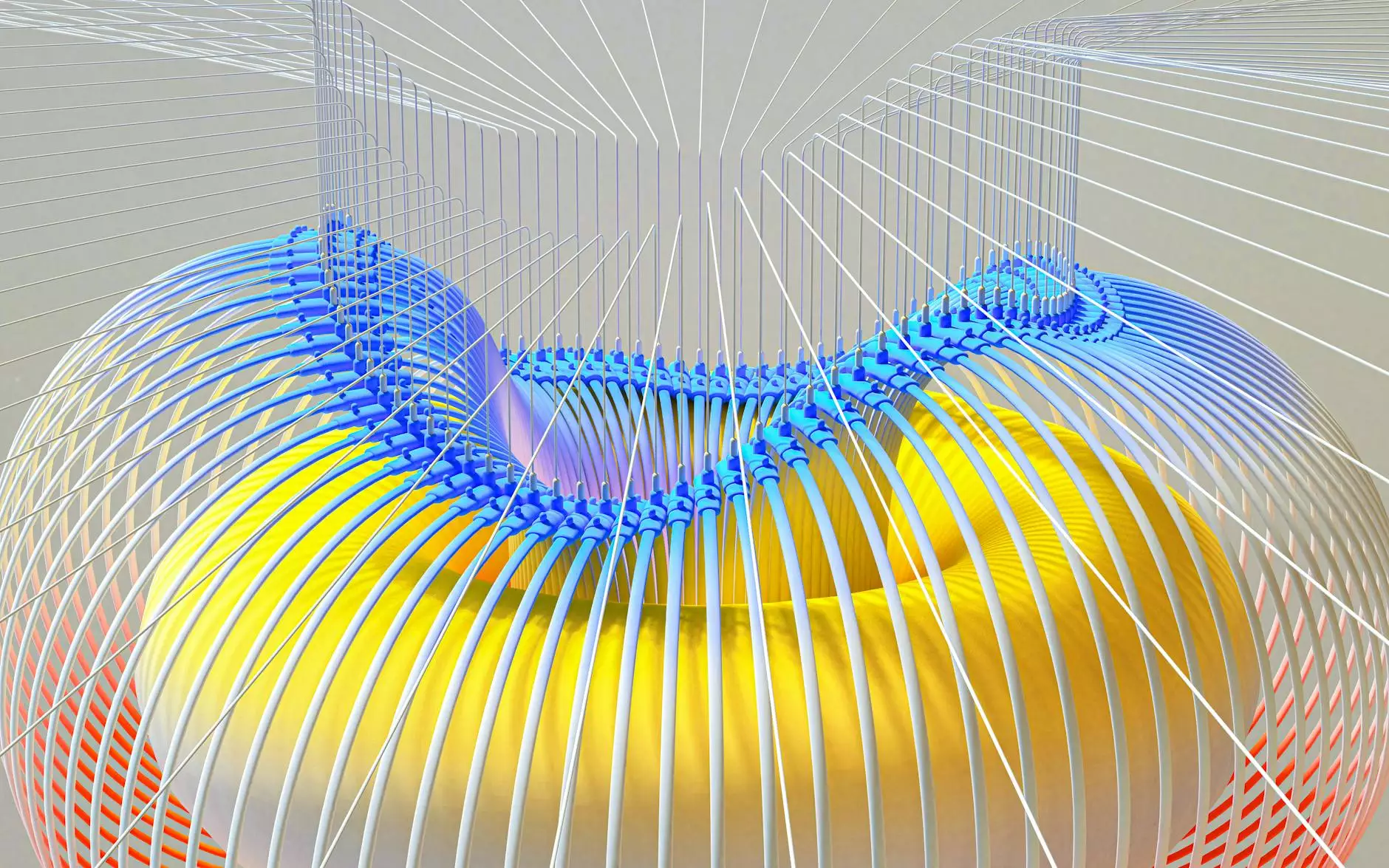

The technology and machinery used by your injection mold supplier play a significant role in the quality of the molds produced. Ensure they utilize state-of-the-art equipment and employ advanced techniques such as:

- 3D Printing: For rapid prototyping and design iterations.

- CNC Machining: Ensures precision in mold manufacturing.

- EDM (Electrical Discharge Machining): Allows for intricate mold designs.

3. Customization and Flexibility

Every business has unique requirements. A reliable injection mold supplier should offer customization options to tailor molds that meet your specific needs. Flexibility in production runs, materials used, and design alterations is essential for adapting to market changes.

4. Communication and Support

Open lines of communication are vital. You should select a supplier who is responsive and willing to collaborate closely with your team. Good communication enables you to understand the process and make informed decisions. Additionally, support should extend beyond production into after-sales services, troubleshooting, and maintenance.

Key Advantages of Partnering with a Respected Injection Mold Supplier

Working with a reputable injection mold supplier offers several significant advantages that can prop up your business in the long run:

1. Quality Assurance

Established suppliers often adhere to strict quality control standards. This means you receive consistently reliable and high-quality molds that meet industry standards. Look for suppliers with certifications that guarantee their processes are certified and trustworthy.

2. Cost-Effective Solutions

While initial costs may seem high, a reputable supplier often leads to lower overall costs by minimizing defects and production waste. In the long term, high-quality molds lead to lower maintenance costs and less downtime in your production line.

3. Speed to Market

With efficient processes and advancements in technology, a skilled injection mold supplier can drastically reduce the time it takes to develop and produce new products. This advantage allows your business to respond swiftly to market demands.

Industry Applications of Injection Molding

The versatility of injection molding allows it to be used in various industries. Here are some key applications:

1. Automotive Sector

Injection molding plays a crucial role in the automotive industry, producing everything from dashboard components to intricate engine parts. This industry demands high precision and durability, and established injection mold suppliers can meet these stringent requirements.

2. Electronics Manufacturing

In the electronics sector, injection molded parts are commonly used for enclosures, connectors, and internal components. Suppliers must ensure that the parts adhere to electrical standards while also being cost-effective.

3. Consumer Goods

From household items like containers and utensils to toys and packaging, injection molding processes are employed extensively in the consumer goods segment. The challenge lies in balancing aesthetics, functionality, and affordability.

How to Evaluate Injection Mold Suppliers

Evaluating potential suppliers can streamline your selection process. Here are some steps to consider:

1. Request for Quotation (RFQ)

Send out RFQs to multiple suppliers detailing your needs. Compare their quotes not just in terms of pricing but also regarding lead times, materials, and services offered.

2. Check References and Reviews

Seek testimonials from previous clients. A good injection mold supplier will have satisfied customers willing to share their experiences.

3. Visit the Facility

If possible, visit the supplier’s production facility. This gives you a firsthand look at their operations, equipment, and quality control practices. It also offers an opportunity to meet the team and build rapport.

4. Start with a Trial Order

Before committing to a long-term partnership, place a small trial order to gauge the supplier's capabilities and service level. This step can help you identify any potential red flags early on.

Conclusion: Making an Informed Decision

The right injection mold supplier can become a valuable partner in your manufacturing journey, enhancing efficiency and product quality. By considering the qualities mentioned above, evaluating potential suppliers, and understanding the broader implications of your choice, you can make informed decisions that benefit your business.

In a competitive market, investing time in finding the right supplier can lead to outstanding results. Remember, the foundation of quality products begins with a great partnership. Choose wisely, and you will reap the rewards for years to come.

For more information and to explore how our services at DeepMould.net can assist you, visit our website or contact our experienced team today!