Comprehensive Guide to Fire Protection Services and the Role of Protein Foam in Modern Fire Safety

Introduction to Fire Protection Services: Ensuring Safety and Compliance

In today’s rapidly evolving industrial landscape, fire protection services have become an essential component for safeguarding lives, property, and the environment. Companies like fatsafire.com specialize in delivering top-tier fire safety solutions tailored to diverse needs across commercial, industrial, and residential sectors.

Fire protection is not merely about installing fire extinguishers; it involves a comprehensive system of prevention, detection, suppression, and management strategies designed to effectively combat fires at their earliest stages. Properly implemented, these systems not only save lives and reduce property damage but also ensure environmental safety and regulatory compliance.

The Evolution of Fire Suppression Technologies: From Traditional to Advanced Solutions

Historically, fire suppression relied heavily on water-based methods, which, although effective for certain classes of fires, posed limitations especially with sensitive equipment or chemical hazards. As industries advanced, so did the need for more sophisticated and environmentally friendly solutions.

Innovations in fire suppression technology include gas-based systems, foam agents, dry chemical powders, and, notably, protein foam solutions, which offer superior performance in specific scenarios. These advanced methods provide rapid response, minimize collateral damage, and comply with stringent safety standards.

Understanding the Role of Protein Foam in Fire Suppression

Among the most innovative fire suppression agents today, protein foam has gained recognition for its exceptional ability to control and extinguish flammable liquid fires, known as Class B fires. This agent is particularly valued in industries dealing with hydrocarbons, chemicals, and other hazardous liquids.

What is Protein Foam?

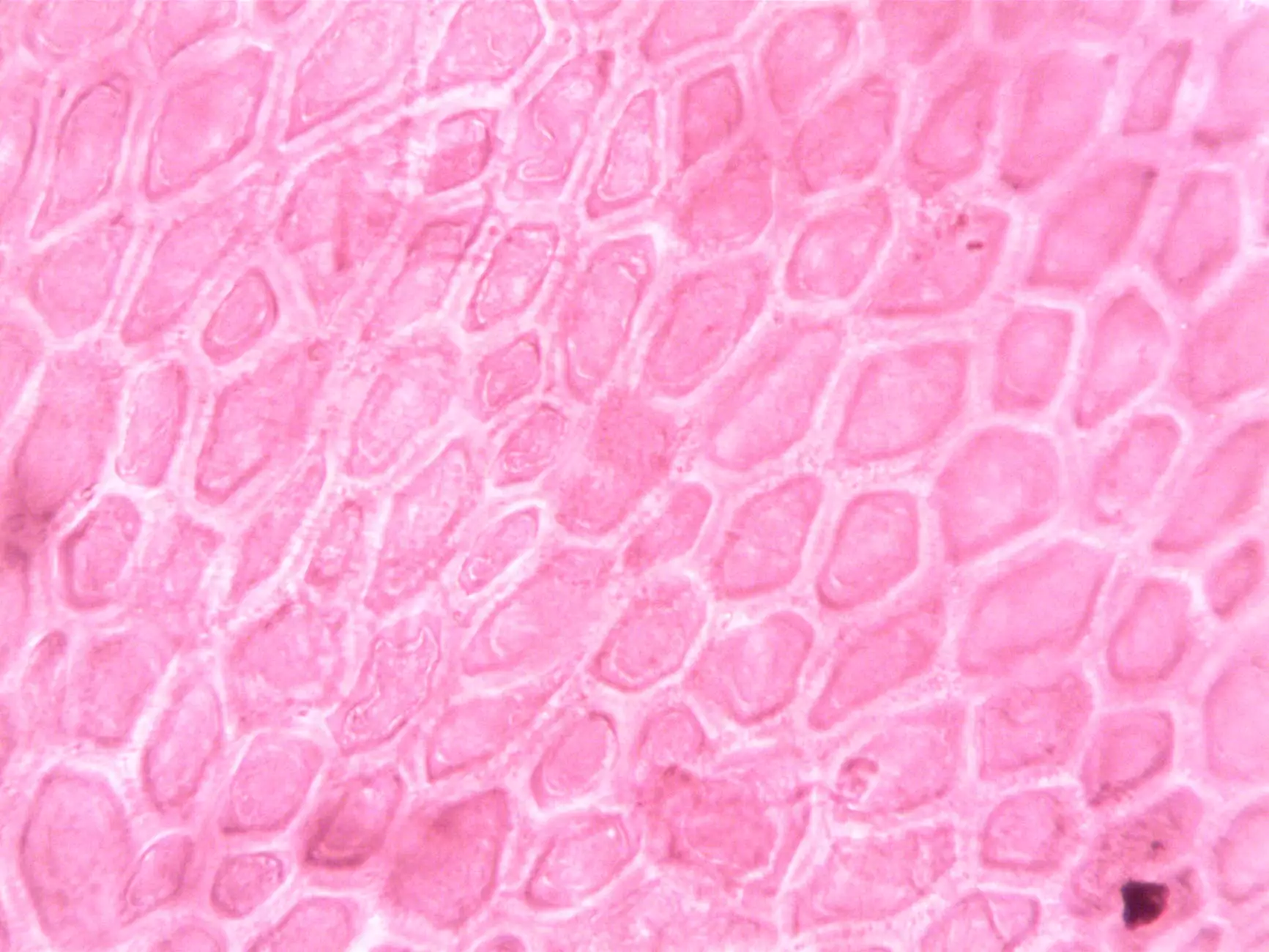

Protein foam is a type of foam concentrate made primarily from modified protein compounds derived from animal by-products, such as blood, bone, and hide. When mixed with water and aerated, it forms a stable, thick foam capable of creating an effective barrier over flammable liquids.

Why is Protein Foam a Preferred Fire Suppression Agent?

- High Efficiency: Protein foam rapidly suppresses flammable liquid fires by smothering the flames and preventing vapors from escaping.

- Adhesion and Stability: Its exceptional adherence to surfaces curtails reignition, making it valuable for large spill areas and storage tanks.

- Environmental Safety: Being biodegradable and non-toxic, protein foam solutions conform to environmental safety standards, reducing ecological impact.

- Cost-Effective: Given its durability and effectiveness, protein foam reduces the need for repeated interventions and long-term maintenance costs.

- Suitable for Various Environments: Its versatility allows use across industrial facilities, airports, petrochemical plants, and marine vessels.

The Science Behind Protein Foam: How It Works

Proteins in foam concentrate undergo physical and chemical changes during the mixing process with water and air, producing a stable foam structure with unique properties:

- Foam Formation: Aerating the concentrate creates billions of microscopic bubbles with a high surface area, which effectively insulate the fuel surface from oxygen.

- Slicking and Smothering: The thick, cohesive foam spreads rapidly over the fuel surface, cutting off oxygen and preventing vapor ignition.

- Cooling Effect: The water content within the foam absorbs heat, lowering the temperature of the fire.

- Reignition Prevention: The durability of the foam prevents re-ignition, even with persistent fuel leaks or spills.

Designing Effective Fire Protection Systems With Protein Foam

Implementing fire protection services that utilize protein foam involves meticulous planning and understanding of site-specific hazards. Critical considerations include:

- Risk Assessment: Identifying potential fire hazards such as storage tanks, chemical processes, or transportation routes.

- System Design: Choosing appropriate foam concentrate ratios, nozzle placement, and coverage area for optimal suppression capabilities.

- Integration with Detection Systems: Incorporating advanced fire detection systems to trigger foam deployment automatically.

- Compliance and Regulations: Ensuring adherence to local safety codes, standards like NFPA 11, and environmental regulations.

- Training and Maintenance: Establishing regular drills, inspections, and maintenance protocols for sustained system effectiveness.

Advantages of Professional Fire Protection Services from fatsafire.com

Choosing a reputable provider such as fatsafire.com guarantees access to:

- Expert Consultation: Tailored fire safety solutions based on thorough site analysis.

- Advanced Equipment: Delivery and installation of state-of-the-art foam systems, including protein foam suppression units.

- Preventive Maintenance: Regular checks and refills to ensure optimal performance during emergencies.

- Compliance Support: Assistance in meeting all regulatory standards and documentation requirements.

- 24/7 Emergency Response: Rapid service to address unforeseen fire safety issues.

Industries Benefiting from Protein Foam and Advanced Fire Protection

Various sectors depend heavily on fire protection services incorporating protein foam, including:

- Petrochemical and Oil & Gas Industries: Protecting storage tanks and processing units from flammable liquid fires.

- Transportation: Ensuring safety on ships, airports, and rail yards managing hazardous materials.

- Manufacturing Plants: Safeguarding chemical plants, refineries, and factories producing combustible products.

- Military and Defense: Special hazard environments requiring robust fire suppression protocols.

- Commercial Storage Facilities: Protecting warehouse inventories from fire risks involving liquids and chemicals.

Ensuring Safety with Regular Training and Testing

Investing in fire safety isn't a one-time task. Continuous employee training and equipment testing are essential to maintain readiness. This includes:

- Emergency Drills: Simulating fire scenarios to familiarize staff with proper evacuation and response procedures.

- System Inspections: Periodic evaluation of foam delivery systems, tanks, and detection devices.

- Refilling and Maintenance: Ensuring foam concentrates are fresh and systems are free from obstructions or damage.

- Record Keeping: Documenting inspections, drills, and maintenance for compliance audits and continuous improvement.

The Future of Fire Protection: Innovations and Sustainability

As industries advance, fire protection systems are also evolving. Emerging trends include:

- Automation and IoT Integration: Smart sensors and IoT devices for real-time monitoring and automatic activation of foam agents.

- Eco-Friendly Agents: Developing biodegradable foams, like protein foam, to reduce environmental impact.

- Hybrid Systems: Combining foam, gas, and other suppression agents for multi-class fire risks.

- Training with Virtual Reality: Using VR simulations to enhance employee preparedness without actual hazards.

Conclusion: Prioritizing Safety Through Expert Fire Protection Solutions

In conclusion, engaging with reputable fire protection services provider like fatsafire.com ensures that your facilities are safeguarded against fire hazards with cutting-edge solutions including protein foam technology. With comprehensive planning, regular maintenance, and continuous training, businesses can significantly reduce risk, ensure regulatory compliance, and create a safer environment for everyone involved.

Remember, fire safety is an ongoing commitment—investing in dependable systems and professional expertise today can prevent devastating losses tomorrow.